hal menarik dari masukan operator lapangan ttg mobil yg baru disuplay

Ada hal menarik dari masukan operator lapangan ttg mobil yg baru disuplay, katanya mobil lama ( no modif – Cuma ganti ban MT ) bebih enak di gunakan – so modifikasi jadinya malah tambah tak enak – goyang – tak lincah ( bumper nongol ) handling jadi aneh.

Artinya modifikasi tak ada benefitnya.

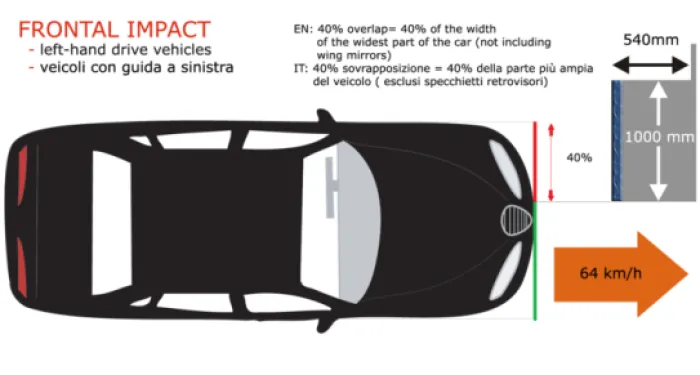

So harus dicari solusi dari deasin awal. Pemasangan bulbar . berat – tak ada crumple zone ( berbahaya & not airbag compatible ) .saat kecelakaan akan merusak chasis & energy tabrakan di terima penumpang tak ada yg terserap ( bisa sangat berbahaya – mematahkan tulang rusuk & kaki )

> solusinya bulbar harus di buat seramping mungkin & berat tidak lebih 50 kg ( kekuatan di peroleh dari tekuan – bahan besi – proses pemotongan /Lasercut – pengelasan –mig . dudukan winch harus diperkuat dgn braket khusus – harus ada Hilift Jack point di bulbar – 3 antena mounting – dudukan aux lamp, braket untuk memperkuat cumplezone di mobil – penambahan crumplezone di bulbar ( harus bisa menyerap energy tabrakan - , ada dudukan untuk 3 keping skid plate . desain bentuk harus aerodinamis untuk deflect abgin & air secara maksimal & tanpa mengurangi volume udara untuk mendinginkan radiator

Jadi pemasangan bullbar ada benefitnya – mobil tetap bisa digunakan pada saat terjadi kecelakaan ringan – dapat meyerap energy tabrakan untuk meminimallan resiko cedera & kerusakan chassis mobil lebih kuat dibanding standart – ada tempat untuk winch /lampu /antenna /skid plate /memperbaiki aprooch agle

Hitungan energi tabrakan

A car with a mass of 2000 kg drives in 60 km/h (16.7 m/s) before it crashes in a massive concrete wall. The front of the car impacts 0.5 m (slow down distance). The impacting force can be calculated as

F = 1/2 (2000 kg) (16.7 m/s)2 / (0.5 m)

= 558 kN ( 558000 joule/meter )

Note that the gravitation force acting on the car is

Fw = m g

= (2000 kg) (9.81 m/s2)

= 19.6 kN

Suspensi – apa yg kita mau cari

Nyaman dikota ( kecepatan 60km < / nayman di high speed 100-150km/ntyaman di jalan rusak 60km

Mofif mesin untuk HP > No, untuk daya tahan oke

Crumple zones are designed to absorb the energy from the impact during a traffic collision by controlled deformation. This energy is much greater than is commonly realized. A 2,000 kg (4,409 lb) car travelling at 60 km/h (37 mph) (16.7 m/s), before crashing into a thick concrete wall, is subject to the same impact force as a front-down drop from a height of 14.2 m (47 ft) crashing on to a solid concrete surface.[7] Increasing that speed by 50% to 90 km/h (56 mph) (25 m/s) compares to a fall from 32 m (105 ft) - an increase of 125%. [7]This is because the stored kinetic energy (E) is given by E = (1/2) mass × speed squared. It increases by the square of the impact velocity.[7][8]

Typically, crumple zones are located in the front part of the vehicle, in order to absorb the impact of a head-on collision, though they may be found on other parts of the vehicle as well. According to a British Motor Insurance Repair Research Centre study of where on the vehicle impact damage occurs: 65% were front impacts, 25% rear impacts, 5% left side, and 5% right side.[9] Some racing cars use aluminium, composite/carbon fibre honeycomb, or energy absorbing foam[10][11] to form an impact attenuator that dissipates crash energy using a much smaller volume and lower weight than road car crumple zones.[12] Impact attenuators have also been introduced on highway maintenance vehicles in some countries.

An early example of the crumple zone concept was used by the Mercedes-Benz engineer Béla Barényi on the mid 1950s Mercedes-Benz "Ponton".[13] This innovation was first patented by Mercedes-Benz in the early 1950s. The patent 854157, granted in 1952, describes the decisive feature of passive safety. Barényi questioned the opinion prevailing till then, that a safe car had to be rigid. He divided the car body into three sections: the rigid non-deforming passenger compartment and the crumple zones in the front and the rear. They are designed to absorb the energy of an impact (kinetic energy) by deformation during collision.

Crumple zones work by managing crash energy, absorbing it within the outer parts of the vehicle, rather than being directly transmitted to the occupants, while also preventing intrusion into or deformation of the passenger cabin. This better protects car occupants against injury. This is achieved by controlled weakening of sacrificial outer parts of the car, while strengthening and increasing the rigidity of the inner part of the body of the car, making the passenger cabin into a 'safety cell', by using more reinforcing beams and higher strength steels. Impact energy that does reach the 'safety cell' is spread over as wide an area as possible to reduce its deformation. Volvo introduced the side crumple zone with the introduction of the SIPS (Side Impact Protection System) in the early 1990s.

When a vehicle and all its contents, including passengers and luggage are travelling at speed, they have inertia / momentum, which means that they will continue forward with that direction and speed (Newton's first law of motion).[18] In the event of a sudden deceleration of a rigid framed vehicle due to impact, unrestrained vehicle contents will continue forwards at their previous speed due to inertia, and impact the vehicle interior, with a force equivalent to many times their normal weight due to gravity. The purpose of crumple zones is to slow down the collision and to absorb energy to reduce the difference in speeds between the vehicle and its occupants.[19]

Seatbelts restrain the passengers so they don't fly through the windshield, and are in the correct position for the airbag and also spread the loading of impact on the body. Seat belts also absorb passenger inertial energy by being designed to stretch during an impact, again to reduce the speed differential between the passenger's body and their vehicle interior.[20] In short: a passenger whose body is decelerated more slowly due to the crumple zone (and other devices) over a longer time survives much more often than a passenger whose body indirectly impacts a hard, undamaged metal car body which has come to a halt nearly instantaneously. It is like the difference between slamming someone into a wall headfirst (fracturing their skull) and shoulder-first (bruising their flesh slightly) is that the arm, being softer, has tens of times longer to slow its speed, yielding a little at a time, than the hard skull, which isn't in contact with the wall until it has to deal with extremely high pressures. The stretching of seatbelts while restraining occupants during an impact, means that it is necessary to replace them if a vehicle is repaired and put back on the road after a collision. They should also be replaced if their condition has deteriorated e.g. through fraying or mechanical or belt mounting faults. In New Zealand it is officially mandatory to replace worn inertia reel type seatbelts only with 'webbing grabber' type belts that have less play and are more effective on older cars.[21]Newer cars have electronically fired pre-tension seatbelts that are timed to work with the airbag firing. Buying used seatbelts is not a good idea even in countries where it is legal to do so, because they may have already been stretched in an impact event and may not protect their new users as they should.

The final impact after a passenger's body hits the car interior, airbag or seat belts is that of the internal organs hitting the ribcage or skull due to their inertia. The force of this impact is the way by which many car crashes cause disabling or life-threatening injury. Other ways are skeletal damage and blood loss, because of torn blood vessels, or damage caused by sharp fractured bone to organs and/or blood vessels. The sequence of energy-dissipating and speed-reducing technologies—crumple zone — seat belt — airbags — padded interior—are designed to work together as a system to reduce the force of the impact on the outside of the passenger(s)'s body and the final impact of organs inside the body. In a collision, slowing down the deceleration of the human body by even a few tenths of a second drastically reduces the force involved. Force is a simple equation: Force = mass X acceleration. Cutting the deceleration in half also cuts the force in half. Therefore, changing the deceleration time from .2 seconds to .8 seconds will result in a 75 percent reduction in total force.[22]

A US Market Ford Escort that has been involved in an offset head-on collision with a Sport Utility Vehicle - showing the raised point of impact - missing the car crumple zone.

A misconception about crumple zones sometimes voiced[citation needed] is that they reduce safety for the occupants of the vehicle by allowing the body to collapse, therefore risking crushing the occupants. In fact, crumple zones are typically located in front of and behind the main body of the car (which forms a rigid 'safety cell'), compacting within the space of the engine compartment or boot/trunk. Modern vehicles using what are commonly termed 'crumple zones' provide far superior protection for their occupants in severe tests against other vehicles with crumple zones and solid static objects than older models or SUVs that use a separate chassis frame and have no crumple zones.

They do tend to come off worse when involved in accidents with SUVs without crumple zones because most of the energy of the impact is absorbed by the vehicle with the crumple zone — however, even for the occupants of the 'worse off' car, this will still often be an improvement — as the result of two vehicles without crumple zones colliding will usually be more hazardous to both vehicle's occupants than a collision that is at least partly buffered.[citation needed]

Another problem is 'impact incompatibility' where the 'hard points' of the ends of chassis rails of SUVs are higher than the 'hard points' of cars, causing the SUV to 'override' the engine compartment of the car.[17] In order to tackle this problem, recent Volvo SUV/off-roaders incorporate structures below the front bumper designed to engage lower-height car crumple zones.

Artinya modifikasi tak ada benefitnya.

So harus dicari solusi dari deasin awal. Pemasangan bulbar . berat – tak ada crumple zone ( berbahaya & not airbag compatible ) .saat kecelakaan akan merusak chasis & energy tabrakan di terima penumpang tak ada yg terserap ( bisa sangat berbahaya – mematahkan tulang rusuk & kaki )

> solusinya bulbar harus di buat seramping mungkin & berat tidak lebih 50 kg ( kekuatan di peroleh dari tekuan – bahan besi – proses pemotongan /Lasercut – pengelasan –mig . dudukan winch harus diperkuat dgn braket khusus – harus ada Hilift Jack point di bulbar – 3 antena mounting – dudukan aux lamp, braket untuk memperkuat cumplezone di mobil – penambahan crumplezone di bulbar ( harus bisa menyerap energy tabrakan - , ada dudukan untuk 3 keping skid plate . desain bentuk harus aerodinamis untuk deflect abgin & air secara maksimal & tanpa mengurangi volume udara untuk mendinginkan radiator

Jadi pemasangan bullbar ada benefitnya – mobil tetap bisa digunakan pada saat terjadi kecelakaan ringan – dapat meyerap energy tabrakan untuk meminimallan resiko cedera & kerusakan chassis mobil lebih kuat dibanding standart – ada tempat untuk winch /lampu /antenna /skid plate /memperbaiki aprooch agle

Hitungan energi tabrakan

A car with a mass of 2000 kg drives in 60 km/h (16.7 m/s) before it crashes in a massive concrete wall. The front of the car impacts 0.5 m (slow down distance). The impacting force can be calculated as

F = 1/2 (2000 kg) (16.7 m/s)2 / (0.5 m)

= 558 kN ( 558000 joule/meter )

Note that the gravitation force acting on the car is

Fw = m g

= (2000 kg) (9.81 m/s2)

= 19.6 kN

Suspensi – apa yg kita mau cari

Nyaman dikota ( kecepatan 60km < / nayman di high speed 100-150km/ntyaman di jalan rusak 60km

Mofif mesin untuk HP > No, untuk daya tahan oke

Crumple zones are designed to absorb the energy from the impact during a traffic collision by controlled deformation. This energy is much greater than is commonly realized. A 2,000 kg (4,409 lb) car travelling at 60 km/h (37 mph) (16.7 m/s), before crashing into a thick concrete wall, is subject to the same impact force as a front-down drop from a height of 14.2 m (47 ft) crashing on to a solid concrete surface.[7] Increasing that speed by 50% to 90 km/h (56 mph) (25 m/s) compares to a fall from 32 m (105 ft) - an increase of 125%. [7]This is because the stored kinetic energy (E) is given by E = (1/2) mass × speed squared. It increases by the square of the impact velocity.[7][8]

Typically, crumple zones are located in the front part of the vehicle, in order to absorb the impact of a head-on collision, though they may be found on other parts of the vehicle as well. According to a British Motor Insurance Repair Research Centre study of where on the vehicle impact damage occurs: 65% were front impacts, 25% rear impacts, 5% left side, and 5% right side.[9] Some racing cars use aluminium, composite/carbon fibre honeycomb, or energy absorbing foam[10][11] to form an impact attenuator that dissipates crash energy using a much smaller volume and lower weight than road car crumple zones.[12] Impact attenuators have also been introduced on highway maintenance vehicles in some countries.

An early example of the crumple zone concept was used by the Mercedes-Benz engineer Béla Barényi on the mid 1950s Mercedes-Benz "Ponton".[13] This innovation was first patented by Mercedes-Benz in the early 1950s. The patent 854157, granted in 1952, describes the decisive feature of passive safety. Barényi questioned the opinion prevailing till then, that a safe car had to be rigid. He divided the car body into three sections: the rigid non-deforming passenger compartment and the crumple zones in the front and the rear. They are designed to absorb the energy of an impact (kinetic energy) by deformation during collision.

Crumple zones work by managing crash energy, absorbing it within the outer parts of the vehicle, rather than being directly transmitted to the occupants, while also preventing intrusion into or deformation of the passenger cabin. This better protects car occupants against injury. This is achieved by controlled weakening of sacrificial outer parts of the car, while strengthening and increasing the rigidity of the inner part of the body of the car, making the passenger cabin into a 'safety cell', by using more reinforcing beams and higher strength steels. Impact energy that does reach the 'safety cell' is spread over as wide an area as possible to reduce its deformation. Volvo introduced the side crumple zone with the introduction of the SIPS (Side Impact Protection System) in the early 1990s.

When a vehicle and all its contents, including passengers and luggage are travelling at speed, they have inertia / momentum, which means that they will continue forward with that direction and speed (Newton's first law of motion).[18] In the event of a sudden deceleration of a rigid framed vehicle due to impact, unrestrained vehicle contents will continue forwards at their previous speed due to inertia, and impact the vehicle interior, with a force equivalent to many times their normal weight due to gravity. The purpose of crumple zones is to slow down the collision and to absorb energy to reduce the difference in speeds between the vehicle and its occupants.[19]

Seatbelts restrain the passengers so they don't fly through the windshield, and are in the correct position for the airbag and also spread the loading of impact on the body. Seat belts also absorb passenger inertial energy by being designed to stretch during an impact, again to reduce the speed differential between the passenger's body and their vehicle interior.[20] In short: a passenger whose body is decelerated more slowly due to the crumple zone (and other devices) over a longer time survives much more often than a passenger whose body indirectly impacts a hard, undamaged metal car body which has come to a halt nearly instantaneously. It is like the difference between slamming someone into a wall headfirst (fracturing their skull) and shoulder-first (bruising their flesh slightly) is that the arm, being softer, has tens of times longer to slow its speed, yielding a little at a time, than the hard skull, which isn't in contact with the wall until it has to deal with extremely high pressures. The stretching of seatbelts while restraining occupants during an impact, means that it is necessary to replace them if a vehicle is repaired and put back on the road after a collision. They should also be replaced if their condition has deteriorated e.g. through fraying or mechanical or belt mounting faults. In New Zealand it is officially mandatory to replace worn inertia reel type seatbelts only with 'webbing grabber' type belts that have less play and are more effective on older cars.[21]Newer cars have electronically fired pre-tension seatbelts that are timed to work with the airbag firing. Buying used seatbelts is not a good idea even in countries where it is legal to do so, because they may have already been stretched in an impact event and may not protect their new users as they should.

The final impact after a passenger's body hits the car interior, airbag or seat belts is that of the internal organs hitting the ribcage or skull due to their inertia. The force of this impact is the way by which many car crashes cause disabling or life-threatening injury. Other ways are skeletal damage and blood loss, because of torn blood vessels, or damage caused by sharp fractured bone to organs and/or blood vessels. The sequence of energy-dissipating and speed-reducing technologies—crumple zone — seat belt — airbags — padded interior—are designed to work together as a system to reduce the force of the impact on the outside of the passenger(s)'s body and the final impact of organs inside the body. In a collision, slowing down the deceleration of the human body by even a few tenths of a second drastically reduces the force involved. Force is a simple equation: Force = mass X acceleration. Cutting the deceleration in half also cuts the force in half. Therefore, changing the deceleration time from .2 seconds to .8 seconds will result in a 75 percent reduction in total force.[22]

A US Market Ford Escort that has been involved in an offset head-on collision with a Sport Utility Vehicle - showing the raised point of impact - missing the car crumple zone.

A misconception about crumple zones sometimes voiced[citation needed] is that they reduce safety for the occupants of the vehicle by allowing the body to collapse, therefore risking crushing the occupants. In fact, crumple zones are typically located in front of and behind the main body of the car (which forms a rigid 'safety cell'), compacting within the space of the engine compartment or boot/trunk. Modern vehicles using what are commonly termed 'crumple zones' provide far superior protection for their occupants in severe tests against other vehicles with crumple zones and solid static objects than older models or SUVs that use a separate chassis frame and have no crumple zones.

They do tend to come off worse when involved in accidents with SUVs without crumple zones because most of the energy of the impact is absorbed by the vehicle with the crumple zone — however, even for the occupants of the 'worse off' car, this will still often be an improvement — as the result of two vehicles without crumple zones colliding will usually be more hazardous to both vehicle's occupants than a collision that is at least partly buffered.[citation needed]

Another problem is 'impact incompatibility' where the 'hard points' of the ends of chassis rails of SUVs are higher than the 'hard points' of cars, causing the SUV to 'override' the engine compartment of the car.[17] In order to tackle this problem, recent Volvo SUV/off-roaders incorporate structures below the front bumper designed to engage lower-height car crumple zones.

Latest News

Untuk lift kit Toyota Fortuner / Vigo-revo / FJ cruiser / Prado 150-120 / Landcrusier 200 series

Untuk lift kit Toyota Fortuner / Vigo-revo / FJ cruiser / Prado 150-120 / Landcrusier 200 series

ada kendala di body mounting yang terlalu dekat ke posisi ban

Design Chasis Toyota untuk memenuhi std keamanan Ancap 5 , body mounting tengah sekaligus penahan ban , agar saat tabrakan ban tertahan chasis. jika mobil telah lift 2 inch , posisi horizontal ban sudah lebih tinggi dari chasis, dan jika " penahan ban " di potong, tak akan mengurangi fungsi penahan ban tersebut

Untuk Offroad betulan Chasis harus di potong atau di Trim .

ada kendala di body mounting yang terlalu dekat ke posisi ban

Design Chasis Toyota untuk memenuhi std keamanan Ancap 5 , body mounting tengah sekaligus penahan ban , agar saat tabrakan ban tertahan chasis. jika mobil telah lift 2 inch , posisi horizontal ban sudah lebih tinggi dari chasis, dan jika " penahan ban " di potong, tak akan mengurangi fungsi penahan ban tersebut

Untuk Offroad betulan Chasis harus di potong atau di Trim .

Sayangi mobil anda!

Sayangi mobil anda!

Jika Anda memiliki SUV diesel, van, atau 4WD, kami harap Anda baca artikel ini ,karena apa yang akan kami katakan akan sangat mengejutkan. Tidaklah berlebihan untuk mengatakan bahwa ada risiko bahwa setiap tangki bahan bakar yang Anda masukkan ke kendaraan Anda membawa risiko kontaminasi air yang dapat menghancurkan seluruh sistem bahan bakar dan bahkan mesin dalam kilometer! Walaupun mengisi dari pertamnina bermerek/ minyak berkualitas Dan tidak terlalu sering bepergian - setiap kendaraan berisiko. Itulah mengapa sangat penting bahwa Anda memasang saringan tambahan solar tgs ke mobil anda

Jadi dari mana datangnya potensi kerusakan, dan mengapa Anda harus memasang tambahan saringan solar tgs kendaraan Anda? Masalahnya adalah dua kali lipat. Pertama, ada peningkatan jumlah kegagalan sistem bahan bakar yang disebabkan oleh air dalam diesel berkat tangki pertamina di seluruh negeri yang menua dan berkarat.

Jadi mengapa Anda tidak bisa mengandalkan filter bahan bakar pabrik Anda, terutama jika memiliki lampu peringatan untuk memberi tahu Anda ketika itu diisi dengan air? Masalahnya adalah saat lampu peringatan menyala, seringkali sudah terlambat. Pada tahap itu, ada peluang bagus bahwa air telah berhasil melewati filter bahan bakar pabrik Anda. Pada saat Anda berhenti di sisi jalan untuk menyelidiki, mungkin sudah terlambat dan kerusakan mungkin sudah dilakukan.

Untuk mobil diesel modren, injeksi commonrail adalah hal umum untuk mendapatkan HP dan torsi yg besar, cuma masalah terbesar dari mesin commonrail adalah kualitas dan kebersihan bahan bakar solar.

untuk mengatsi kualitas solar yg buruk , sangat disarankan memasang extra filter. pilihan extra filter juga ngak boleh sembarangan, harus sesuai sengan kapasitas mesin( Flow & Micron ). juga harus diperhatikan kualitas desain breket dan selang, yang mana breket dan selang sebaiknya tinggal pasang " plug and play "

- Satu-satunya Filter dengan 5 lapisan stratapore yg mampu menyaring emulsi ( air yg telah bercampur dengan solar )

- Satu-satunya Filter dengan 5 lapisan stratapore yg mampu menyaring emulsi ( air yg telah bercampur dengan solar )

- Extra Fuel Filter TGS memang didesain khusus untuk aplikasi sebagai Pre filter mesin kapasitas 8000cc – 500 hp

- Dgn Flow rate antara 90 GPH , tidak akan menyebabkan resistansi dari pemasangan extra fuel Filter ( untuk mesin 2500cc 170 HP Cuma membutuhkan 32 GPH )

- Stratapore memiliki daya serap kotoran yg besar & efisien ( 30 kali lebih besar dibanding saringan OEM biasa /cellulosa - capasitas hingga 72 gram ), sehingga bisa bertahan hingga pemakaian 30.000km

- Aplikasi pre filter tidak mencopot selang OEM & ukuran diameter selang tetap seperti OEM ( tidak terjadi hambatan di selang )

- Untuk aplikasi di mesin Tanpa Common rail, mengunakan FS1000 10 micron. pemasangan filter tambahan setelah filter utama OEM

- Untuk Aplikasi di mesin Common rail, mengunakan filter 10 micron absolut , pemasangan filter tambahan sebelum filter utama OEM

Jika Anda memiliki SUV diesel, van, atau 4WD, kami harap Anda baca artikel ini ,karena apa yang akan kami katakan akan sangat mengejutkan. Tidaklah berlebihan untuk mengatakan bahwa ada risiko bahwa setiap tangki bahan bakar yang Anda masukkan ke kendaraan Anda membawa risiko kontaminasi air yang dapat menghancurkan seluruh sistem bahan bakar dan bahkan mesin dalam kilometer! Walaupun mengisi dari pertamnina bermerek/ minyak berkualitas Dan tidak terlalu sering bepergian - setiap kendaraan berisiko. Itulah mengapa sangat penting bahwa Anda memasang saringan tambahan solar tgs ke mobil anda

Jadi dari mana datangnya potensi kerusakan, dan mengapa Anda harus memasang tambahan saringan solar tgs kendaraan Anda? Masalahnya adalah dua kali lipat. Pertama, ada peningkatan jumlah kegagalan sistem bahan bakar yang disebabkan oleh air dalam diesel berkat tangki pertamina di seluruh negeri yang menua dan berkarat.

Jadi mengapa Anda tidak bisa mengandalkan filter bahan bakar pabrik Anda, terutama jika memiliki lampu peringatan untuk memberi tahu Anda ketika itu diisi dengan air? Masalahnya adalah saat lampu peringatan menyala, seringkali sudah terlambat. Pada tahap itu, ada peluang bagus bahwa air telah berhasil melewati filter bahan bakar pabrik Anda. Pada saat Anda berhenti di sisi jalan untuk menyelidiki, mungkin sudah terlambat dan kerusakan mungkin sudah dilakukan.

Untuk mobil diesel modren, injeksi commonrail adalah hal umum untuk mendapatkan HP dan torsi yg besar, cuma masalah terbesar dari mesin commonrail adalah kualitas dan kebersihan bahan bakar solar.

untuk mengatsi kualitas solar yg buruk , sangat disarankan memasang extra filter. pilihan extra filter juga ngak boleh sembarangan, harus sesuai sengan kapasitas mesin( Flow & Micron ). juga harus diperhatikan kualitas desain breket dan selang, yang mana breket dan selang sebaiknya tinggal pasang " plug and play "

- Satu-satunya Filter dengan 5 lapisan stratapore yg mampu menyaring emulsi ( air yg telah bercampur dengan solar )

- Satu-satunya Filter dengan 5 lapisan stratapore yg mampu menyaring emulsi ( air yg telah bercampur dengan solar )

- Extra Fuel Filter TGS memang didesain khusus untuk aplikasi sebagai Pre filter mesin kapasitas 8000cc – 500 hp

- Dgn Flow rate antara 90 GPH , tidak akan menyebabkan resistansi dari pemasangan extra fuel Filter ( untuk mesin 2500cc 170 HP Cuma membutuhkan 32 GPH )

- Stratapore memiliki daya serap kotoran yg besar & efisien ( 30 kali lebih besar dibanding saringan OEM biasa /cellulosa - capasitas hingga 72 gram ), sehingga bisa bertahan hingga pemakaian 30.000km

- Aplikasi pre filter tidak mencopot selang OEM & ukuran diameter selang tetap seperti OEM ( tidak terjadi hambatan di selang )

- Untuk aplikasi di mesin Tanpa Common rail, mengunakan FS1000 10 micron. pemasangan filter tambahan setelah filter utama OEM

- Untuk Aplikasi di mesin Common rail, mengunakan filter 10 micron absolut , pemasangan filter tambahan sebelum filter utama OEM

A DEEPER LOOK AT SPRING VS. AIR

A DEEPER LOOK AT SPRING VS. AIR

Suspension systems contribute to a tractor-trailer’s road handling and ride quality (the vertical acceleration to which a tractor-trailer is exposed). Keeping the tires in contact with the road as much as possible, suspension systems help minimize the amount of jarring (bumps, vibrations) for improved load-carrying ability, protecting the trailer and the freight inside from being damaged.

Suspension systems contribute to a tractor-trailer’s road handling and ride quality (the vertical acceleration to which a tractor-trailer is exposed). Keeping the tires in contact with the road as much as possible, suspension systems help minimize the amount of jarring (bumps, vibrations) for improved load-carrying ability, protecting the trailer and the freight inside from being damaged.